When it comes to metallurgical processes, every degree counts. Every erosion matters. And every delay adds up.

But what if the key to more stable, longer-lasting furnaces is hidden in something as sharp as sand? That’s where green silicon carbide comes in.

Green silicon carbide is no longer just a precision grinding material. It’s proving itself as a high-performance asset in metallurgy—from steelmaking furnaces to non-ferrous metal smelting and even thermal management.

It’s not hype. It’s hard science, smart strategy, and serious results. Stick with me—I’ll show you where it fits in your furnace, why it resists what others can’t, and how it quietly makes your production line more efficient.

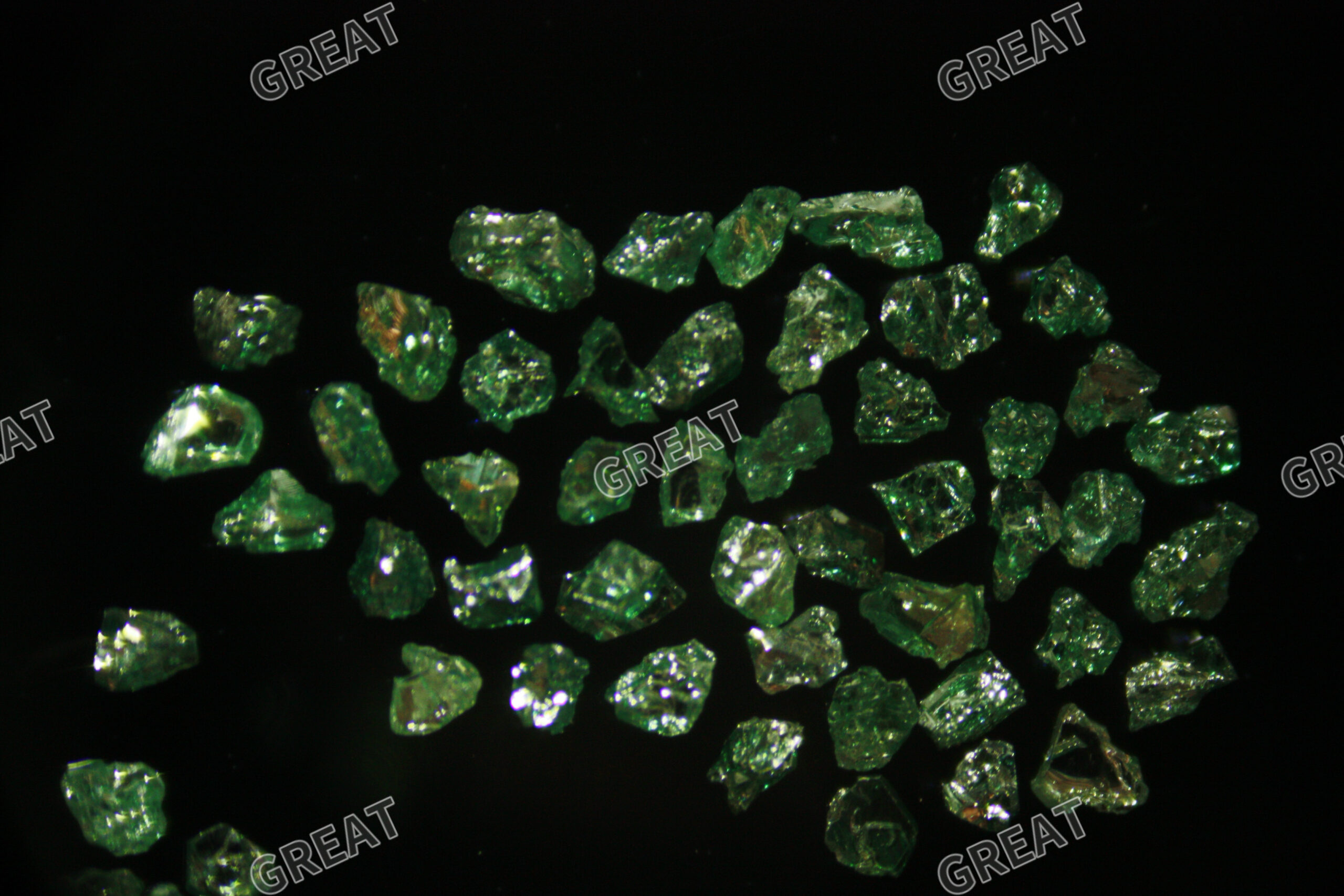

What makes green silicon carbide different?

Let’s start with the basics. Green silicon carbide is manufactured at high temperatures using high-purity silica sand and petroleum coke.

It’s sharper and purer than black silicon carbide, with silicon carbide content typically over 99%—which means more thermal stability and less reaction residue.

This material is extremely hard (second only to diamond), and its refractory temperature is around 1850°C, while dissociation happens only above 2600°C.

In layman’s terms? It can take the heat—and stay structurally sound while doing it.

Why do steelmakers care?

Because furnace linings don’t last forever.

Green SiC’s resistance to thermal shock, erosion, and slag attack makes it ideal for lining high-temperature kilns and furnaces—especially in critical zones like the furnace bottom, slag line, and wall lining.

The result? Longer service life, fewer shutdowns, and better thermal insulation over time. In some cases, it has extended refractory lifespan by over 30%.

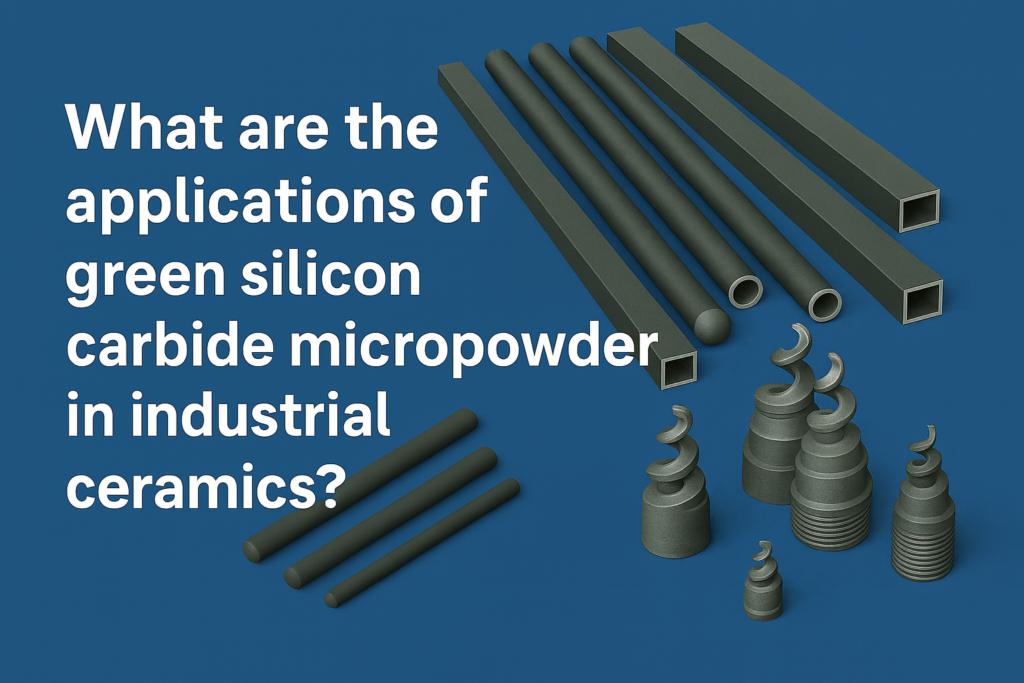

Isn’t it too brittle for heavy industrial use?

Good question. That’s where SiC ceramics come in.

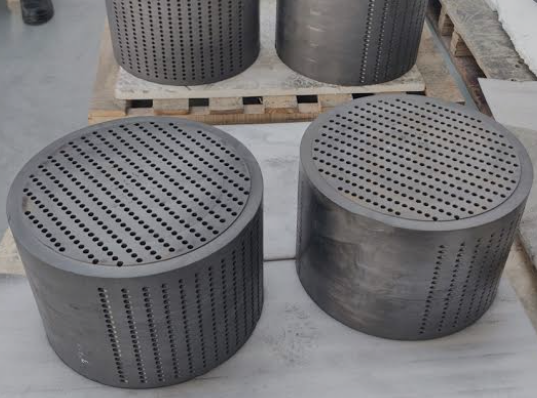

When we blend green silicon carbide into ceramic crucibles, we’re creating parts that can not only withstand heat—but also resist chemical corrosion from molten non-ferrous metals, like copper and zinc. This makes it perfect for harsh smelting conditions.

Especially in aluminum, copper, and zinc industries, green SiC parts outlast traditional ceramic or graphite-based crucibles.

Can green SiC really improve heat efficiency?

Absolutely. One of the silent killers in any metallurgical operation is heat loss.

Green silicon carbide has excellent thermal conductivity, meaning it doesn’t just survive heat—it moves it efficiently.

When used in heat exchangers or heat-retaining linings, it helps keep energy where it belongs: inside the furnace.

That means better thermal efficiency, lower fuel consumption, and a smaller carbon footprint. That’s good for your bottom line—and great for your ESG score.

So, what does all this mean for you?

You’re not just buying raw materials. You’re managing supply chain risk, production stability, and long-term cost efficiency. Green silicon carbide helps tick all those boxes:

- High heat resistance for fewer refractory failures

- Corrosion resistance for cleaner metal processing

- Thermal efficiency for lower operational costs

- Long-term availability for peace of mind

And when it comes from us—GREAT Abrasive—you’re not just getting a product.

We can provide stable and high-quality service for all kinds of green silicon carbide abrasives you need.

You’re getting a consistent, high-quality material, backed by real people who actually care if your next melt goes smoothly.