When the defense industry is searching for lighter, stronger, and more heat-resistant materials, Green Silicon Carbide (SiC) always stands out.

Whether it’s armor systems, missile components, or high-temperature ceramic structures, SiC delivers performance that traditional materials simply cannot match.

In this article, you will get a clear view of why Non-Pressure SiC Powder and Granulated SiC Powder are widely used across modern military technology and what advantages they bring.

What Makes Green Silicon Carbide Valuable in Defense?

Green SiC is known for its:

- Ultra-high hardness (second only to diamond & B₄C)

- Excellent thermal conductivity

- Oxidation resistance at >1800°C

- Low impurity content

- High fracture strength

- Outstanding wear resistance

Because of this combination, it is ideal for military-grade ceramics, lightweight armor, propulsion systems, and advanced aerospace structures.

👉 To learn more about SiC, here’s a helpful technical overview: What is Silicon Carbide?

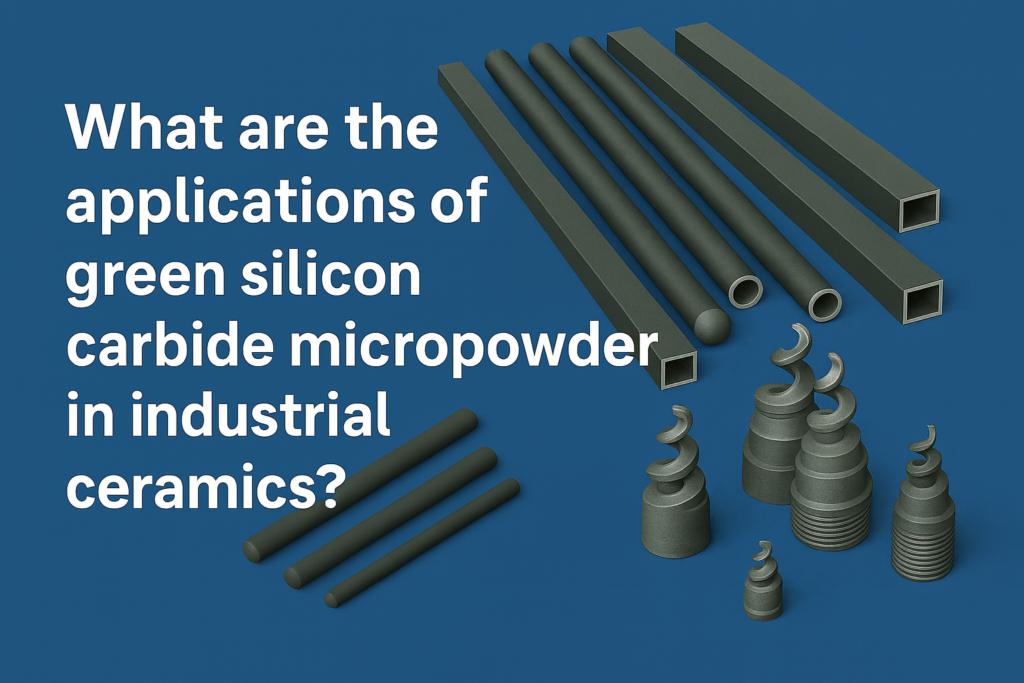

1. Non-Pressure Green SiC Powder: Precision for High-Performance Ceramics

Non-pressure SiC powder features very fine PSD, high purity, and strong sintering activity. It plays an essential role in the following applications:

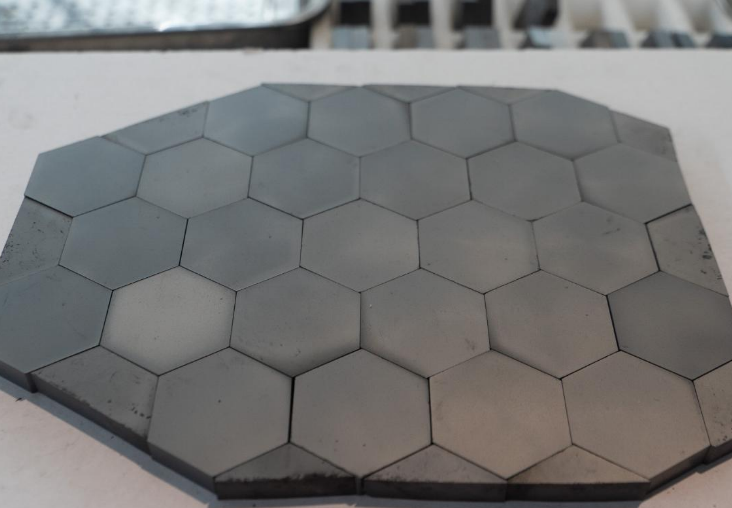

1.1 Ceramic Armor Plates

Used in:

- Soldier ballistic plates

- Lightweight armor panels for tactical vehicles

- Helicopter floor armor

Why? It provides high ballistic resistance with weight far lower than conventional metal armor.

Learn more about ceramic armor mechanisms

1.2 Missile & Rocket Thermal Components

Non-pressure SiC powder is used to manufacture:

- Rocket nozzle throats

- Combustion chamber liners

- Thermal protection tiles for high-speed vehicles

Its ability to survive extreme heat makes it the right fit for hypersonic environments.

1.3 High-Precision Military Components

Including:

- Radar cooling baseplates

- High-speed bearings

- Anti-wear coatings

- Long-life friction parts in military machinery

The combination of high thermal conductivity + wear resistance ensures stability even in harsh battlefield conditions.

2. Granulated SiC Powder: Ideal for Large & Complex Military Structures

Granulated powder provides excellent flowability, which is perfect for:

- Dry pressing

- CIP (Cold Isostatic Pressing)

- Injection molding

- Large structural ceramic forming

2.1 Large Ceramic Armor Modules

Granulated SiC is used to create:

- Tank ceramic armor blocks

- Armored vehicle protection boards

- Drone and UGV lightweight armor modules

These parts must be stable, large, and uniform—granulated powder ensures that.

2.2 Missile Structural Components

Used to produce:

- Guidance system housings

- Lightweight support rings

- High-strength insulating structures

The benefits?

- High stiffness

- Low density

- Excellent thermal stability

2.3 Aerospace Heat-Resistant Structures

Granulated SiC powder is ideal for forming:

- Heat shields

- Leading edges

- High-temperature sensor casings

Its ability to maintain strength at extreme temperatures makes it suitable for next-generation aircraft and space systems.

3. Common Military Uses Shared by Both Powders

Regardless of form, Green SiC is essential in:

3.1 High-End Grinding & Polishing

For:

- Aerospace turbine blades

- Optics for targeting systems

- Military-grade infrared lenses

3.2 Thermal Management Systems

SiC ceramics are increasingly replacing alumina in:

- Radar transmitters

- High-power laser systems

- Airborne electronic modules

3.3 Propellant Additives

Some solid rocket propellant formulas include SiC as a high-temperature reinforcement, improving structural integrity.

4. Why the Defense Industry Prefers Green SiC Over Other Materials

Compared to alumina, boron carbide, and traditional metals, SiC offers:

| Material | Hardness | Density | Heat Resistance | Typical Use |

| Green SiC | ★★★★☆ | Medium | ★★★★★ | Armor, nozzles, structures |

| Alumina | ★★★☆☆ | High | ★★★☆☆ | Low-cost armor |

| Boron Carbide | ★★★★★ | Ultra-low | ★★★★☆ | Premium armor |

| Metal Steel | ★★☆☆☆ | Very high | ★★☆☆☆ | Vehicle armor |

Green SiC stands at the sweet spot between performance and cost, especially in high-temperature and high-strength defense components.

5. Final Thoughts: Why Military Engineers Choose SiC From Trusted Manufacturers

Defense components demand zero compromise in quality. A small deviation in PSD, purity, or density can lead to:

- Poor sintering

- Fragile structure

- Lower ballistic performance

- Overheating in thermal systems

Working with a stable SiC supplier helps military manufacturers achieve:

- Consistent mechanical properties

- Reliable forming performance

- Repeatable high-temperature resistance

- Optimized cost for mass production

Interested in high-purity Green SiC powders for defense ceramics?

Contact us for customized PSD, purity, and granulation tailored to your military ceramic applications.