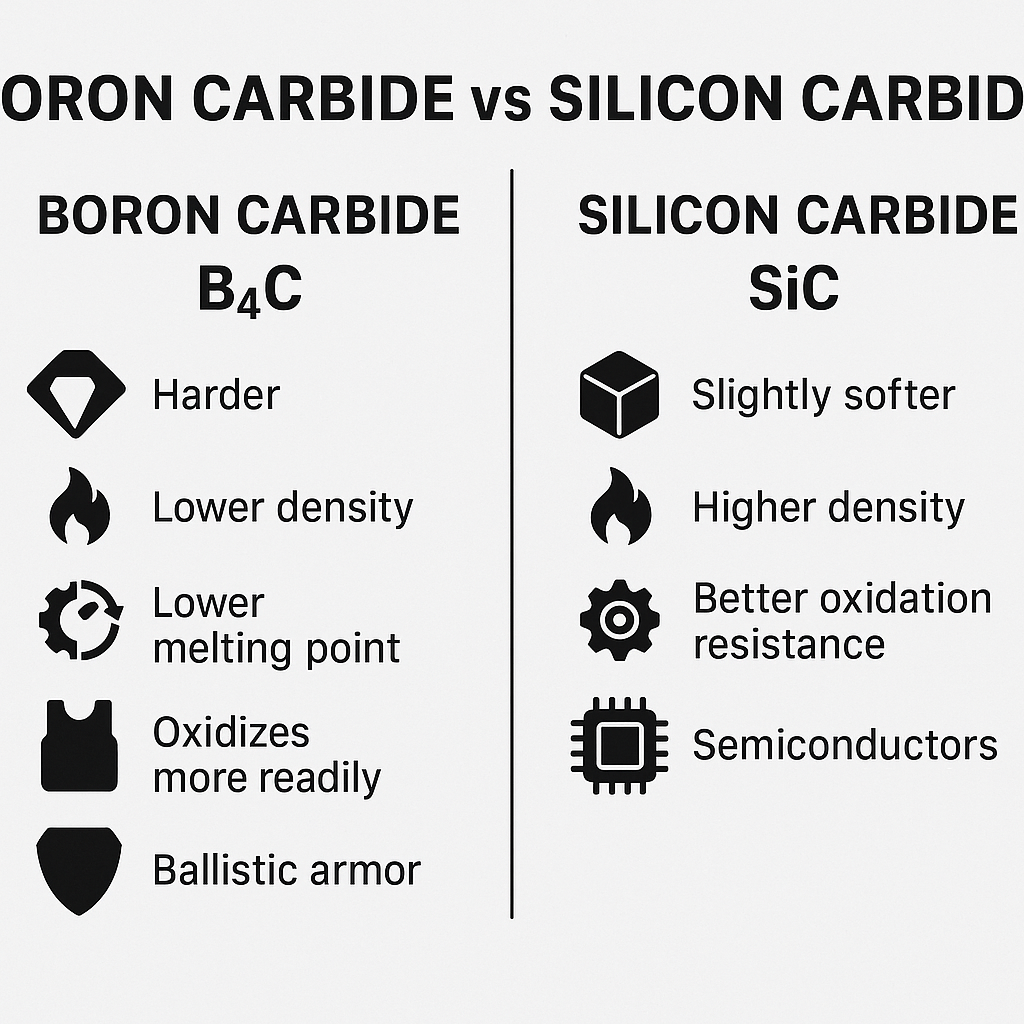

Silicon carbide (SiC) and boron carbide (B₄C) are two of the most important advanced ceramics used today.

Both materials are known for their extreme hardness, wear resistance, and high chemical stability, but they differ in density, toughness, oxidation resistance, cost, and industrial applications.

This article provides a comprehensive comparison of B₄C and SiC, explaining their physical properties, performance at high temperatures, typical applications in armor and semiconductors, and market outlook.

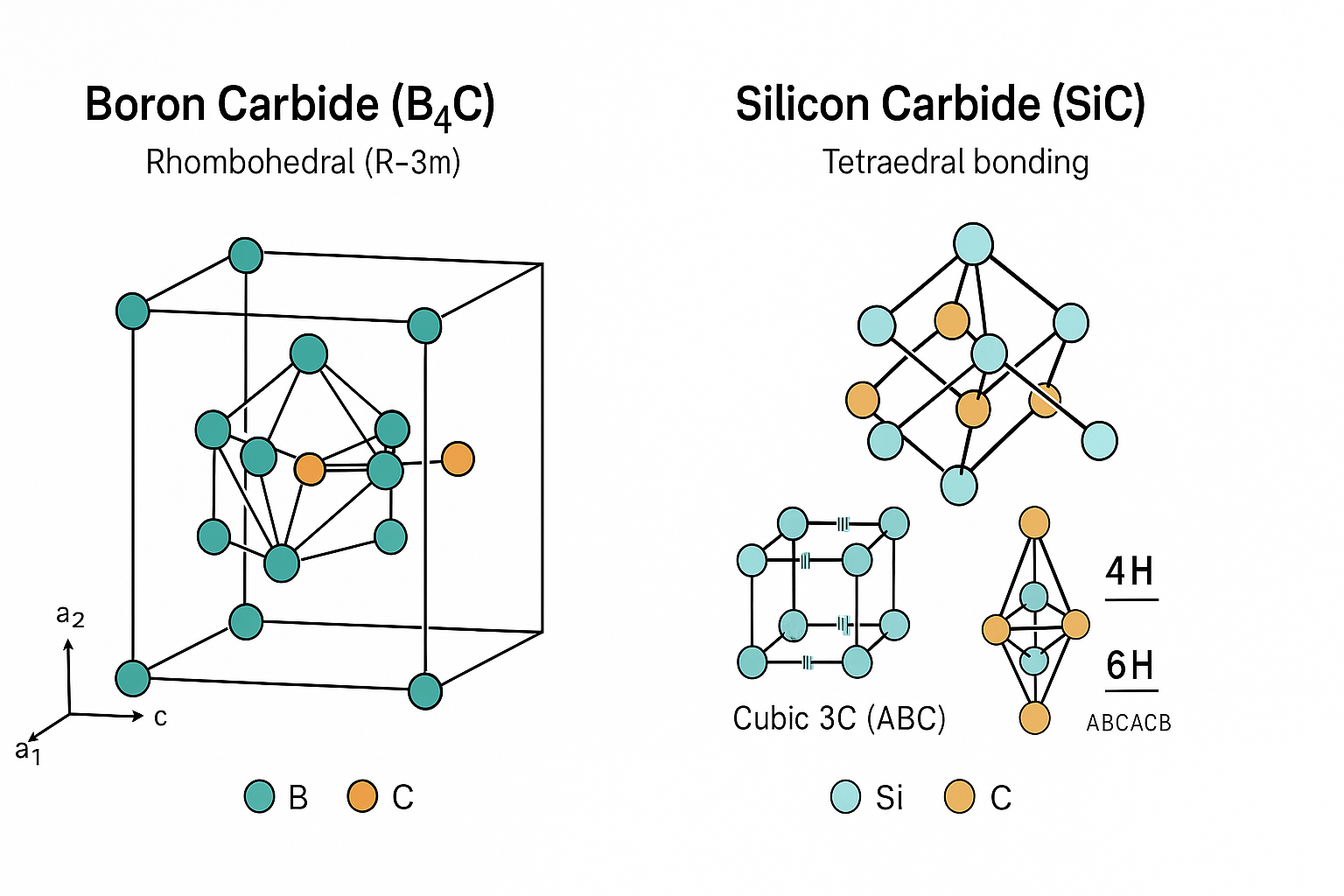

1. Chemical Composition and Structure

- Boron Carbide (B₄C): Formula B₄C, rhombohedral structure with B₁₂ icosahedra and C–B–C chains.

- Silicon Carbide (SiC): Formula SiC, diamond-like tetrahedral bonding, commonly in cubic (3C-SiC) or hexagonal (4H-SiC, 6H-SiC) forms.

2. Physical Properties

- Hardness: B₄C is harder (Mohs ~9.5), ranking just below diamond and cubic boron nitride. SiC is slightly softer (Mohs ~9.2–9.3).

- Density: B₄C is lighter (~2.52 g/cm³) compared to SiC (~3.21 g/cm³), making it attractive for lightweight armor.

- Elastic Modulus & Toughness: SiC has higher fracture toughness, giving it better resistance to thermal shock and repeated impacts.

- Melting Point: B₄C ~2450 °C vs. SiC ~2700 °C.

3. High-Temperature and Oxidation Resistance

- SiC: Outstanding oxidation resistance, forming a stable SiO₂ surface layer at high temperatures. Suitable for aerospace and high-temp electronics.

- B₄C: Begins oxidizing above ~500 °C, with lower thermal shock resistance. Limited in long-term high-temperature applications.

4. Industrial Applications

4.1 Armor and Defense

- B₄C: Best for lightweight ballistic plates and personal protection, excelling in single-hit resistance.

- SiC: Preferred when cost control and multi-hit resistance are priorities; widely used in mid- to high-end ceramic armor.

4.2 Abrasives and Wear Components

- B₄C: Performs best under extreme wear conditions.

- SiC: Dominates the global abrasive market thanks to lower cost and mature processing.

4.3 Electronics and Semiconductors

- SiC: A wide-bandgap semiconductor (3.2–3.4 eV), used in power electronics, electric vehicles, high-temperature chips, and aerospace electronics.

- B₄C: Insulating, with little role in semiconductor technology.

4.4 Nuclear Applications

- B₄C: Effective neutron absorber, used in nuclear reactor control rods.

- SiC: Limited nuclear application.

5. Cost and Manufacturing

- B₄C: Expensive, sensitive to processing, limited scalability.

- SiC: Large-scale production, lower costs, mature machining methods.

6. Armor Reliability: Single-Hit vs. Multi-Hit

- B₄C: Exceptional for single-shot penetration resistance, but brittle under multi-hit scenarios.

- SiC: More reliable in multi-hit conditions due to better crack resistance and process consistency.

7. Selection Guidelines for Engineers

- Lightweight & Single-Hit Maximum Protection → Choose B₄C.

- Cost-Effective, Multi-Hit Resistance → Choose SiC.

- High-Temperature or Semiconductor Devices → SiC only.

In practice, hybrid designs (e.g., ceramic strike face + composite backing) are used to balance weight, protection, and durability.

8. Market Trends (2025 Outlook)

- B₄C: Demand growing in aerospace, nuclear, and defense, but remains niche due to cost.

- SiC: Experiencing rapid adoption in EVs, semiconductors, and power devices. Expanding wafer production (150 mm / 200 mm) is expected to further reduce costs over the next three years.

Quick Comparison Table

| Category | Boron Carbide (B₄C) | Silicon Carbide (SiC) |

| Hardness | Higher (~9.5 Mohs) | Slightly lower (~9.2–9.3 Mohs) |

| Density | Lighter (~2.52 g/cm³) | Heavier (~3.21 g/cm³) |

| Toughness | Lower fracture toughness | Higher toughness |

| Oxidation Resistance | Oxidizes >500 °C | Excellent, protective SiO₂ layer |

| Armor Use | Lightweight, single-hit focus | Cost-effective, multi-hit resistance |

| Electronics | Not applicable | Wide-bandgap semiconductor |

| Nuclear | Neutron absorber | Limited role |

| Cost | High, niche | Lower, scalable |

Conclusion

- Boron Carbide (B₄C): Ideal when lightweight design and maximum hardness are critical, such as in high-end ballistic armor and nuclear systems.

- Silicon Carbide (SiC): The versatile choice for abrasives, armor, semiconductors, and high-temperature applications, with stronger market growth due to cost-effectiveness and scalability.

Looking forward, SiC is set to dominate mass markets, while B₄C retains its role in high-value defense and nuclear applications.