Why Carborundum (Silicon Carbide) is the Key to Longer-Lasting, High-Performance Products

If your business relies on precision, durability, and cost efficiency, the right material choice can make or break your project. Carborundum (silicon carbide) is more than just an abrasive — it’s a strategic advantage. From grinding wheels that outlast the competition to semiconductor components that drive high-efficiency power systems, this material delivers measurable results. Whether you’re sourcing for manufacturing, automotive, metallurgy, or electronics, understanding carborundum’s types, uses, and advantages will help you secure consistent quality, reduce downtime, and maximize ROI.

What Is Carborundum (Silicon Carbide)?

Carborundum is the trade name for silicon carbide (SiC), a crystalline compound of silicon and carbon. It’s valued for its extreme hardness, thermal stability, and resistance to wear and corrosion.

1. Chemical Composition

- Formula: SiC (Silicon + Carbon)

- Structure: Crystalline

- Forms: Powders, grains, bonded or coated products

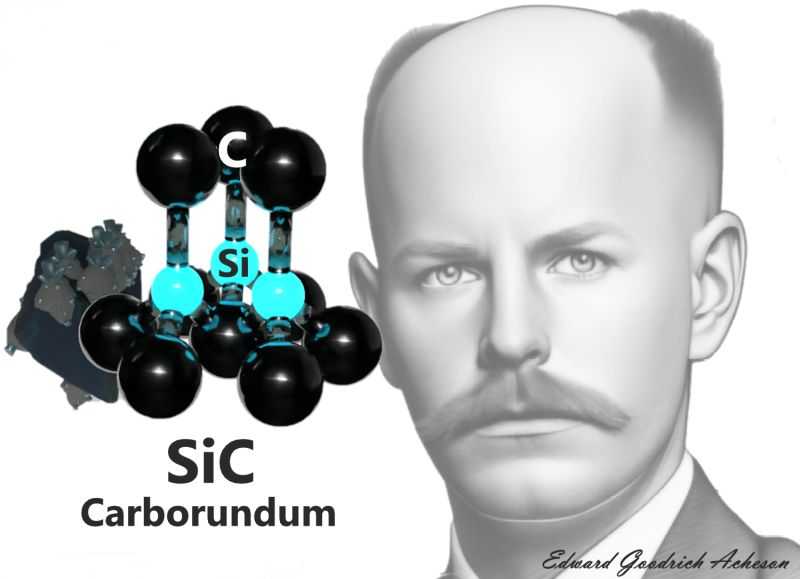

2. A Brief History

In 1891, Edward Goodrich Acheson was attempting to create artificial diamonds when he accidentally synthesized silicon carbide. He named it carborundum — combining “carbo” (Latin for carbon) and “corundum” (a naturally hard mineral).

Types of Carborundum (Silicon Carbide) and Related Hard Materials

| Type | Chemical Formula | Key Properties | Common Applications |

| Silicon Carbide (SiC) | SiC | Extreme hardness, high thermal conductivity, corrosion resistance | Grinding wheels, cutting tools, sandpapers, refractory linings |

| Boron Carbide (B₄C) | B₄C | Ultra-high hardness, excellent wear resistance, lightweight | Armor plating, blasting nozzles, abrasives |

| Tungsten Carbide (WC) | WC | Dense, very hard, impact-resistant | Cutting inserts, drill bits, wear-resistant coatings |

Key Applications of Carborundum (Silicon Carbide)

- Abrasives

- Core ingredient in grinding wheels, sandpaper, and cutting tools

- Shapes and finishes metals, ceramics, and glass

- Refractory Materials

- Used in linings for furnaces, kilns, and reactors

- Resists thermal shock and abrasion at high temperatures

- Metallurgy

- Serves as a deoxidizing agent in steelmaking

- Improves metal purity, strength, and ductility

- Used in wear-resistant foundry parts

- Electronics

- Enables high-efficiency semiconductors and power devices

- Used in LEDs, inverters, and EV drive systems for better thermal and electrical performance

- Automotive

- Applied in high-performance ceramic brake discs

- Improves stopping power, reduces fade, and extends service life

- Essential in EV electronics for efficiency gains

Advantages of Carborundum (Silicon Carbide)

| Advantage | Benefit in Industry |

| Exceptional hardness | Longer tool life, reduced wear and replacement costs |

| High thermal conductivity | Efficient heat dissipation in extreme environments |

| Chemical inertness | Reliable performance in corrosive or oxidizing atmospheres |

| Electrical properties | Superior performance in high-voltage and high-frequency devices |

Conclusion

From heavy-duty abrasives to precision electronic components, carborundum is a material that excels under pressure. Its unmatched hardness, thermal management ability, and resistance to chemical attack make it a foundation of modern manufacturing and technology. As industries evolve, expect SiC-based materials to appear in even more demanding roles.

FAQs

Q1:What is carborundum? A: A crystalline compound of silicon and carbon (SiC), known for its hardness and thermal conductivity.

Q2:Who discovered it? A: Edward Goodrich Acheson in 1891.

Q3:What are the main types? A: Silicon carbide (SiC), boron carbide (B₄C), and tungsten carbide (WC).

Q4:Which industries use it? A: Abrasives, refractories, metallurgy, electronics, and automotive.

Q5:Why choose carborundum? A: For its extreme hardness, wear resistance, heat tolerance, corrosion resistance, and superior electrical performance.