Ever wondered how brown fused alumina plays a pivotal role in refractory materials?

Characteristics of Brown Fused Alumina

Brown fused alumina is a powerhouse in the refractory materials industry, boasting characteristics that make it indispensable.

High Hardness: Ranking 9th on the Mohs hardness scale, brown corundum’s durability ensures stability and wear resistance. This is essential for maintaining the integrity of refractory materials in demanding environments.

High Purity: The high purity level of brown fused alumina enhances the overall performance and quality of refractory products, ensuring they meet stringent industry standards.

!image description

Impact Resistance, Oxidation Resistance, and Corrosion Resistance

Brown fused alumina excels in resisting impact and maintaining chemical stability. This resistance allows it to perform optimally in high-temperature environments where other materials might fail.

High Temperature Resistance: Even at extreme temperatures, brown fused alumina resists pulverization and cracking. This reliability is crucial for maintaining the structural integrity of refractory materials in high-heat settings.

Application Fields of Brown Fused Alumina

Brown fused alumina’s versatility makes it a staple in various refractory material applications.

Iron Ditch Castable: As a primary raw material, brown corundum provides stability and wear resistance, essential for iron ditch castables used in high-temperature environments.

Refractory Ramming Material: Brown fused alumina is used in ramming materials, providing fire-resistant protection in areas subjected to intense heat loads.

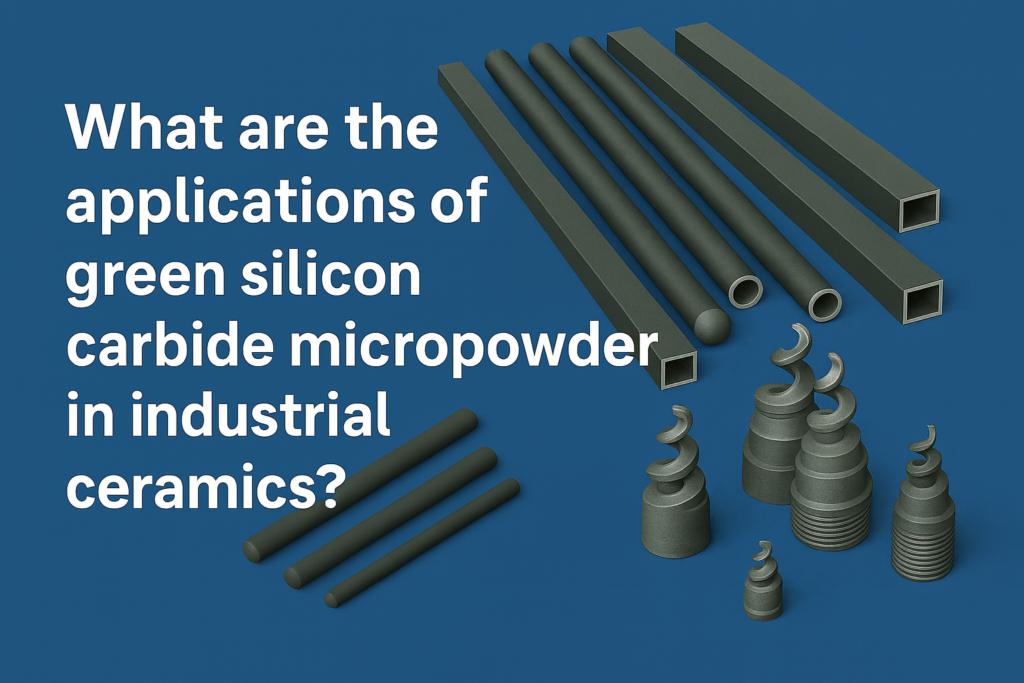

!image description

Aggregate for Pouring Material Filling: In the production of pouring materials, brown fused alumina is often utilized as a filling aggregate. This addition enhances the strength and fire resistance of the material, making it suitable for high-stress applications.

Components of Long Spout, Skateboard, and Ladle: Brown fused alumina is integral in the manufacture of these components, which are essential in the metallurgical industry.

Quality Control of Brown Fused Alumina

Ensuring the quality of brown fused alumina is vital for its effectiveness as a refractory material.

Impurity Content: The presence of impurities like calcium hexaaluminate, calcium plagioclase, spinel, and rutile can significantly impact performance. Strict quality control measures are necessary to ensure the alumina content meets the required standards.

Testing for Alumina and Carbon Content: Regular testing ensures that the alumina content is within acceptable ranges and that the carbon content is appropriate, thus maintaining the material’s quality and performance.

Smelting Process of Brown Fused Alumina

The smelting process is critical in determining the quality of brown fused alumina.

Traditional vs. Secondary Refining Smelting: Traditional smelting processes can introduce impurities, but secondary refining smelting technology helps remove these impurities, enhancing the stability and performance of the final product.

Conclusion

Brown fused alumina’s application in refractory materials is multifaceted, providing essential properties like hardness, wear resistance, and high-temperature stability. With the right smelting technology and stringent quality control, it remains a key raw material in manufacturing high-quality refractory products.